KNOWLEDGE, COURAGE, INNOVATION

I have proudly taken up the challenge that is innovating and managing in such a rich, noble company. We are all proud of what we do, we are proud of who we are. Knowledge, courage, innovation.

This is Abate Basilio’s spirit.

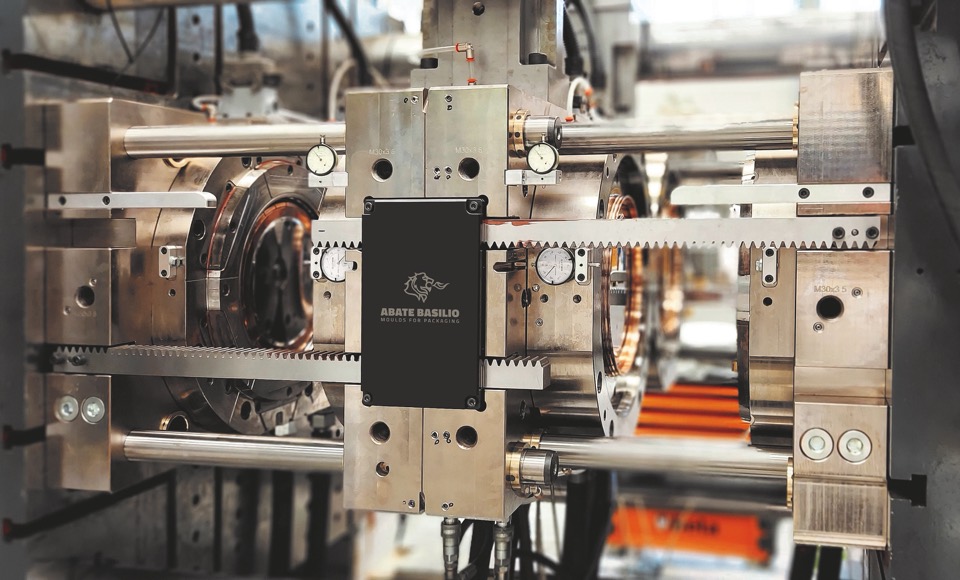

Abate Basilio

Moulds for Packaging

Moulds for buckets and containers

Abate Basilio, a worldwide leader in the manufacture of high performance moulds including moulds for truncated cone-shaped containers intended for food and chemical use, offers several patented solutions for closing buckets and containers; thanks to the innovative Quadrowings® and Triplock® patents it also offers simple, double or triple closing systems which can be integrated with the extraordinary IMA® technology which allows the handle to be automatically inserted.

Thin Wall Packaging Molds

Abate Basilio moulds are renown for high quality, reliability and efficiency, every mould is built with great care and attention. Thanks to the expertise acquired over 47 years, our company has developed IML technology which allows decorative images to be directly applied to the product during the moulding process.

Containers come in different shapes and sizes and depending on volumes required per year, we offer 2, 4, 6 or more cavities including product weight saving advantages with ultra-thin wall sections as well as different types of sealing closure designs.

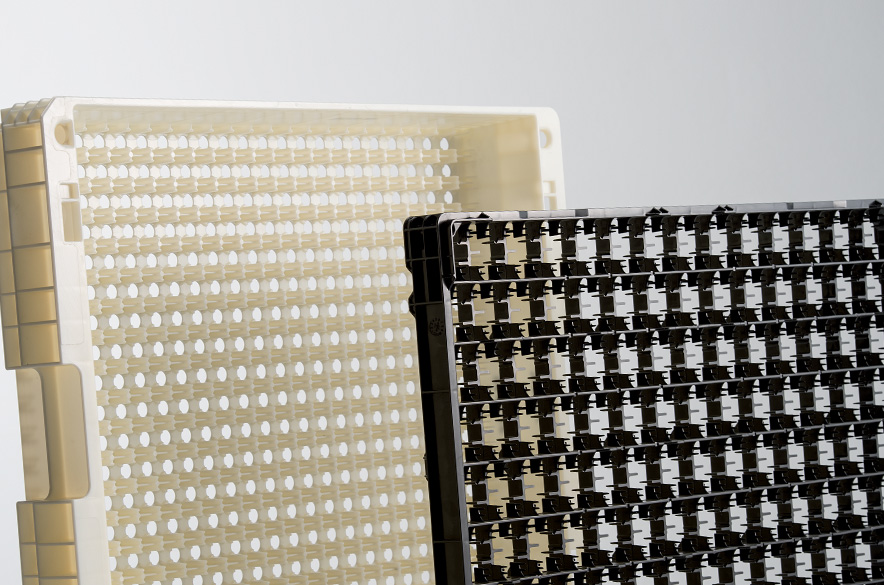

Moulds for crates

Abate Basilio’s wide experience in planning and manufacturing injection moulds for crates has resulted in a variety of products. Crates of any shapes and sizes: crates for industrial and technical logistics, for food use, for bottles as well as shaped one-way crates. Thanks to the commitment of our technical department, we manufacture crates with reduced wall thickness, folding sides, with handles, and with side decoration thanks to IML technology, as well as foldable crates

Our planning department also offers our customers quick prototyping as well as FEM (finite element method) and logistic analysis of the final product.

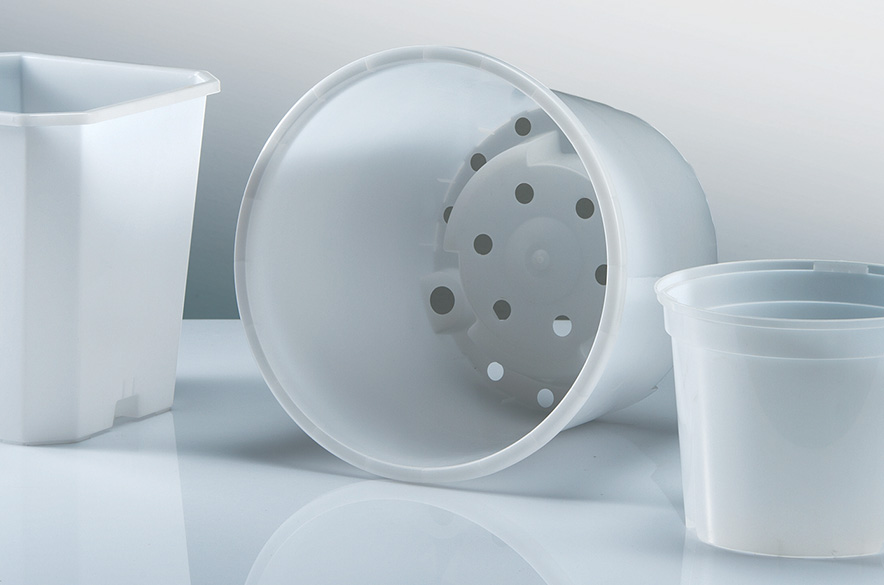

Moulds for flower pots

Thanks to the patents developed over the years, namely Square the circle®, Innercore®, Vaba® and Flexomould®, Abate Basilio is able to plan and manufacture moulds for pots by using unique technology, such as the elastic system for opening the draining holes, which provide logistic and production advantages to the customer. We use high grade materials which ensure longevity, reliability and performance of the mould over the time.

Patents and technologies

Abate Basilio have eight innovative and unique patents granted. Very few companies in this field boast a comparable spirit of innovation and capability, such a well defined vision for the future. In the last forty years Abate Basilio has been setting trends in the design of injection moulds, allowing companies to offer improved, safer and more efficient products to the market.

The company’s experience together with its research & development ensure an on-going technical advancement aimed at providing effective solutions to its customers in the field of injection moulds for packaging. Our expert knowledge of materials and their applications allows us to obtain incomparably reliable production systems.

Our patented technologies include mould cooling, centring, in-mould handle assembly, modularity of the cavities, ejection of the product and the design of new containers with customized closing systems specific for food and industrial purpose.

Our patents offer our customers greater advantages than the competition.

-

handle moulding and assembly onto the container directly carried out into the mould.

-

container with double lock lid and tear-off band

-

container with triple lock lid and tear-off band

-

labelling during the moulding process

-

cavity change on the same mould

-

advanced system to centre the moulds

-

enhanced

cooling system -

ejection valve with a safe closure

-

injection and

compression system

Processes

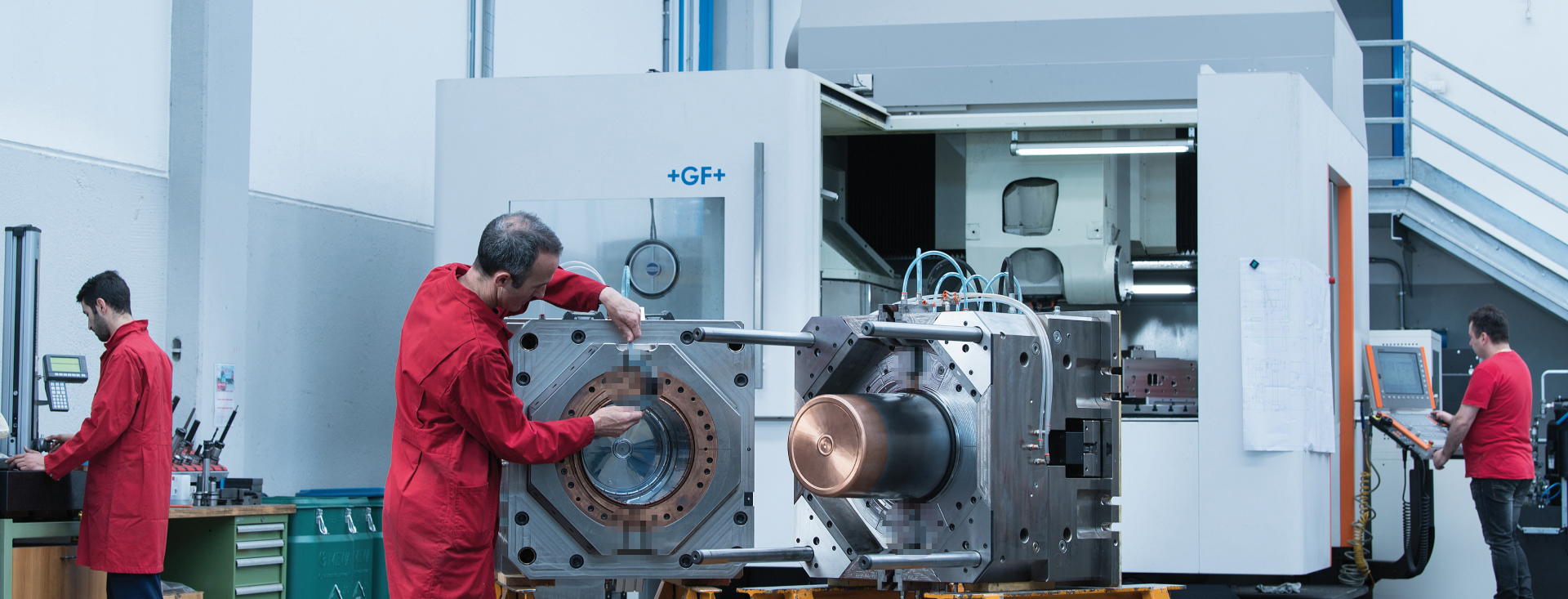

Thanks to its technology, flexibility and analytical approach, Abate Basilio does not only manufacture high performance moulds for the injection of plastic materials, but also provides customized solutions for any project. Thanks to the control of the entire production chain, from planning to delivery, each mould ensures unique quality, durability and performance.

Analysis

and planning

Abate offers a service of consultancy and analysis of the customer’s needs specific for each project. A specific technical knowledge is required for each sector, from food industry to chemicals, logistics etc., in order to be able to design and manufacture the more appropriate mould for a specific product.

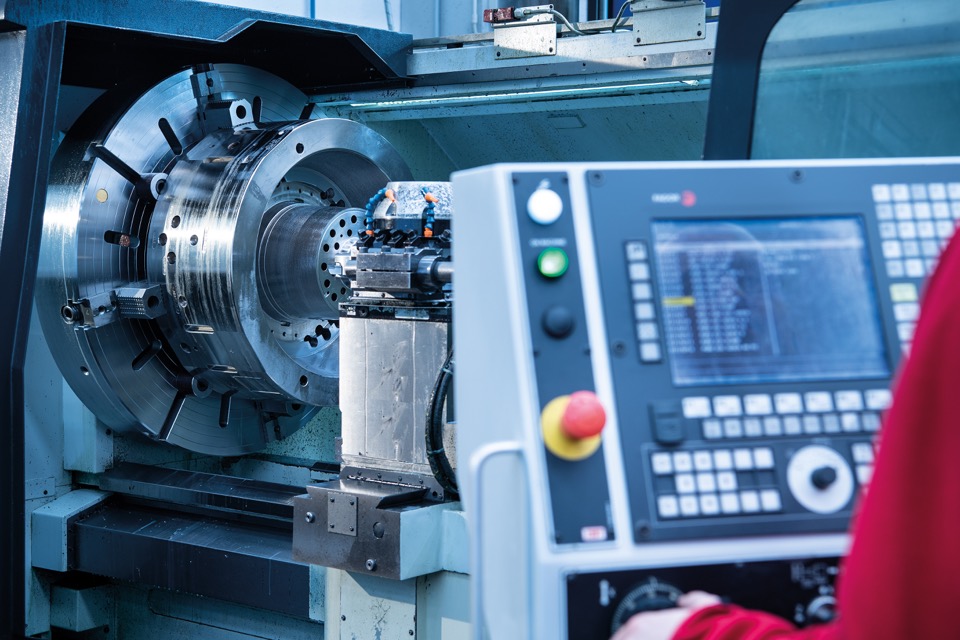

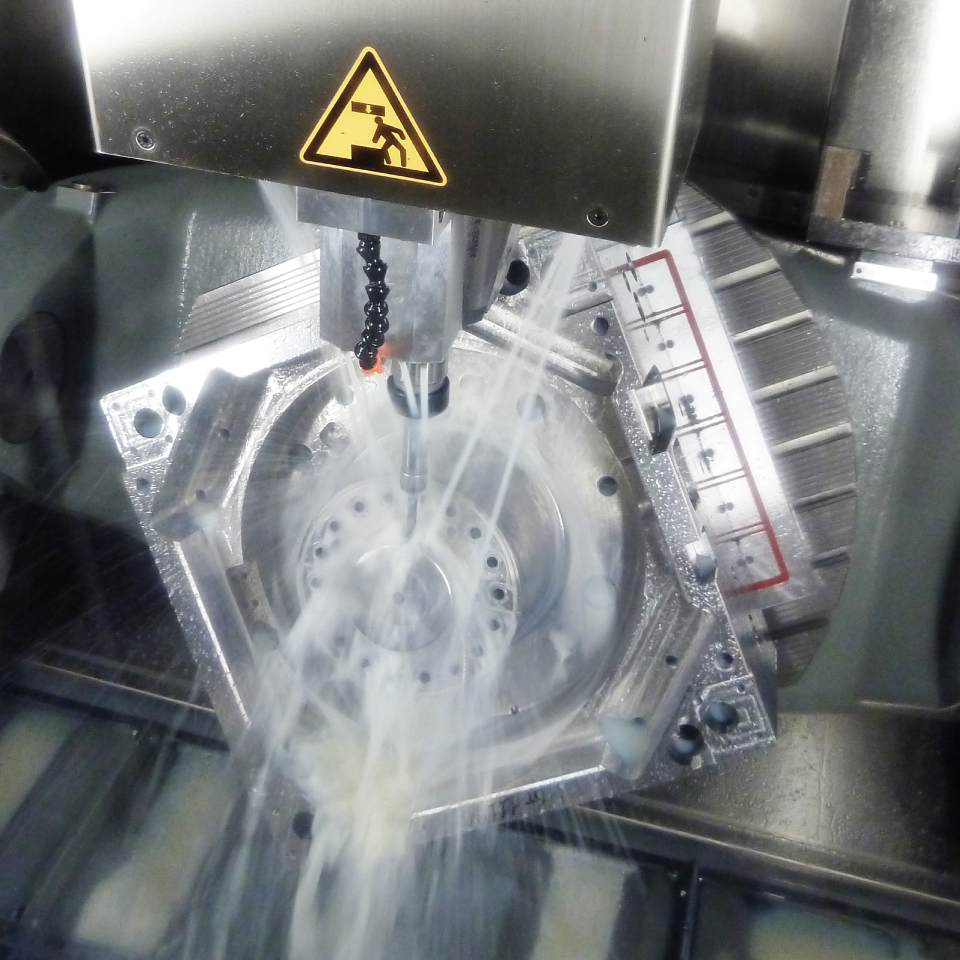

Construction

and testing

Our production line includes 5-axis machining centres with fully automatic tool and pallets changers which allow us to achieve maximum repeatability and quickest throughput. Our machines are equipped with a laser control of the real dimensions directly obtained during the process in order to achieve the maximum precisions.

Maintenance

and after-sale

Our technical department ensures a fast, reliable and precise after-sale service. 95% of the company production is destined to be exported to different countries located over 5 continents. Our company has always given support to customers all over the world thanks to reliable planning of the mould and availability of spare parts which are guaranteed for 20 years.